Resinzwood Knot Hole resin is primarily used to fill knot holes, cracks, and voids, with the resin drying clear in colour. Resin artists also widely use it for coasters, jewelry, top-coating artwork, and small tabletops. At Resin Wood Tables NZ, we aim to simplify choosing the proper epoxy by providing all the necessary information about each resin type. Today, we're focusing on our Resinzwood Knot Hole Resin, which can be poured up to 15mm deep in small areas, while a depth of 10mm is recommended for larger areas to avoid an exothermic reaction, known as a flash cure.

the resin drying clear in colour. Resin artists also widely use it for coasters, jewelry, top-coating artwork, and small tabletops. At Resin Wood Tables NZ, we aim to simplify choosing the proper epoxy by providing all the necessary information about each resin type. Today, we're focusing on our Resinzwood Knot Hole Resin, which can be poured up to 15mm deep in small areas, while a depth of 10mm is recommended for larger areas to avoid an exothermic reaction, known as a flash cure.

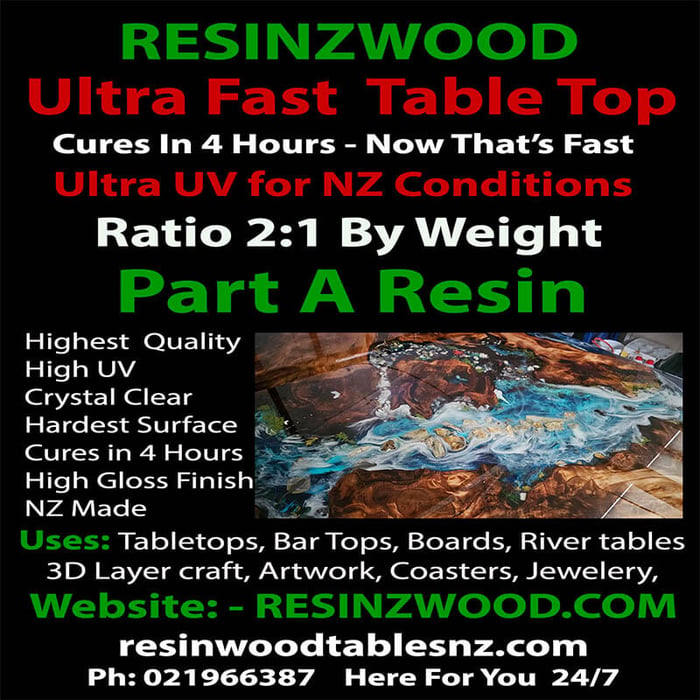

Resin artists widely use Resinzwood Knot Hole resin for crafting coasters and other artworks, including for final coats on artwork. From the maker's perspective, there are better products for final coats, like our Resinzwood Ultra Fast resin, which cures in 4 hours. Now, the Ultra Fast is the best for all top coatings of tables and artworks. Resinzwood Ultra Fast epoxy is a 2:1 ratio by weight, or our Passionart Craft resin1:1 ratio by volume.

Many people love Resinzwood Knot Hole resin as a one-stop product for every occasion. It works very well for layering and creating lacing effects.

Resinzwood Knot hole resin cures in eight hours and is completely hard for demolding after 24 hours. Like all epoxy resins, this product will continue to get harder over time, reaching a hardness of 80D on the hardness scale.

Fun Facts about Resinzwood Knot Hole Resin

- Do you offer Online tutorials? - Here at Resin Wood Tables, we have online tutorials for you to follow, with videos to explain the process. We also offer seven-day-a-week phone support or video calls should you need our help

- Do You Offer Phone and or Video call support? - Some companies only offer minimal support, if you can call it that, and it is usually only via email. - We offer phone and video call support seven days a week

- What is the depth I can pour to? This is important as you may pour the resin too deep, resulting in an exothermic reaction due to your room being too hot. Our Knot Hole resin can be poured to more than 15mm in depth if the room is more relaxed, say below 18c, but we advise staying at 5 to 10mm deep at 20c to 25c room temp until you understand the product.

- What is the UV additive, and how long will it last? Many types of UV additives are used, some designed to trick the eye only. Most companies will tell you your resin will not start to yellow inside for the first 12 months - Resinzwood Knot Hole resin has evolved to retain clarity for years before showing signs of yellowing. There may be more advancements in the product in the years to come, but we are more than pleased with its current form. Testing and performance estimations show that our high UV allows for decades inside under filtered light.

- What is the hardness rating of the resin? There are many ways and formulas for making resin, and most resins range on a scale from D65, which is quite soft, to D90, which is very hard and scratch-resistant. - Resinzwood Knot Hole resin is D75 to D80 once fully cured.

- How long does it take for the resin to cure? Resinzwood Knot Hole resin cures in eight hours and completely hard after 24 hours in the right conditions. Generally, we like to leave our resin for a few days in a high-temperature room to harden up after this stage. All epoxy resins will continue to harden for months.

- What degree of heat can the resin withstand? Ok, this is a fascinating topic that I will do a separate page about, as withstanding temps and actual temp that will not create imperfections are two different things. Many companies push this boundary with false or incorrect claims or stretch the truth. A resin may withstand 260F, but that does NOT mean it will NOT leave imperfections in your top. We openly tell our clients that you should not put a boiling hot cup of coffee onto your table and expect no damage, especially for the first few months of curing. Our resin will withstand more than 260c, but that is a different scale.

- Will Colours be a problem? Colours will not cause a big problem when adding them to your resin; you must be aware of some things. Firstly, by adding dye or powder pigments, you are changing the chemical makeup of the resin, increasing the exothermic reaction and cure time. Powders cure all resins faster, with dyes not so much. Add acrylic paint to resin, but never more than a 2% volume ratio. Generally, we add up to 1 teaspoon or 10 grams per liter of resin with our Colour Passion powders and dyes.

- What happens if my resin fails? It is likely your fault if your resin has a problem like sticky spots, overheating or flash cure, or failing to cure, no matter the brand. - Here at Resin Wood Tables NZ, we talk with our clients, get photos and videos, and problem-solve to ensure this does not happen again. Sometimes, it can be a manufacturing problem or a bottle mislabelled, and this has only ever occurred once with us, thank God, but it can happen. We will get you to return the product, and if we have the same issue, we will give you a New product.

Method for mixing Resinzwood Knot Hole Resin

- Calculate the volume needed using our resin calculator on our site.

- Add the proportion of hardener first to a container, then add the volume of resin. This ensures all resin molecules come into contact with the hardener molecules.

- Mix with a flat stick or paddle slowly so not to aerate the product.

- Pour from one container to another a few times. This is known as the two-bucket method.

- Apply thinly over your substrate/timber using your hand in a rubber glove or with a brush.

- Do not push brush up and down as this will aerate the resin and make it go milky.

- Flame the torch off to ensure all microbubbles are dispersed.

- Never sand between coats. Sanding has the potential to create dust spots in your work.

For more info, email resinwoodtablesnz@gmail.com or Call Paul on 021966387, 7 days a week, from 8 am to 10pm. I am here to help you get the most out of all our products.

Download PDF File Here Mixing Instructions & Safety Guide.

Updates Info

This page will be updated over time. If you have questions you want answered, we will add them here.

For the best, clearest resins in Aotearoa, NZ, check out our full range of Highest Quality Epoxy Resins.

For more info and support, call Paul 021966387....