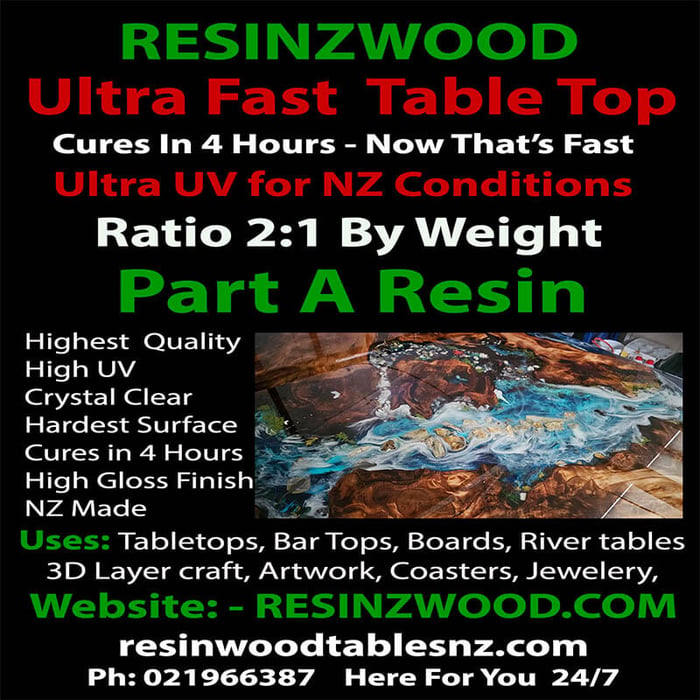

Resinzwood Ultra-Fast Tabletop Resin is a 2 to 1 Ratio by Weight. Resinzwood Ultra-

BUY NOW Resinzwood Ultra-Fast Resin has been specifically designed and made right here in Aotearoa, New Zealand, as a high-performing High UV epoxy unique resin that will cure in 4 to 5 hours. Ultra-Fast Tabletop Resin cured means it is touch set and should be left for at least 24 hours before further steps like sanding for the next coat. Here at Resin Wood Tables NZ, we like to leave our finished table tops for 48 hours before polishing them if we feel we need to, but generally, Ultra-Fast Tabletop Resin does not need any polishing as once poured correctly, you will have a perfect glass finish. This tabletop resin will increase hardness in warm to hot environments as time passes. It can be sanded after 24 hours for another coat. See below for instructions on how to sand and reapply another coat.

Aotearoa, New Zealand, as a high-performing High UV epoxy unique resin that will cure in 4 to 5 hours. Ultra-Fast Tabletop Resin cured means it is touch set and should be left for at least 24 hours before further steps like sanding for the next coat. Here at Resin Wood Tables NZ, we like to leave our finished table tops for 48 hours before polishing them if we feel we need to, but generally, Ultra-Fast Tabletop Resin does not need any polishing as once poured correctly, you will have a perfect glass finish. This tabletop resin will increase hardness in warm to hot environments as time passes. It can be sanded after 24 hours for another coat. See below for instructions on how to sand and reapply another coat.

This unique blend can be challenging to use, especially on more oversized tables requiring larger resin volumes. With the Resinzwood step-by-step guide, you will gain new skills as you become a Resinzwood Epoxy Guru. We developed this resin for people who need to finish a job in a small amount of time. Suited for craftsmen who work in a not-so-dust-free environment, the Resinzwood Ultra-Fast Tabletop Resin will go off fast, helping to eliminate the amount of time the resin is vulnerable to having things land in it.

Resinzwood Ultra-Fast Tabletop Resin Method

Calculate the amount of resin you need. This can be done using the resin calculator at resinzwood.com. Accuracy is essential when mixing Part A and Part B. This product is designed for pouring up to 6mm deep in 18 to 22c in most cases, but here at our shop, we have our resin room set to 27.5 degrees Celsius as we have found this to be the perfect temp to pour and cure the epoxy without the need for polishing once the job is complete. Cure Time of 3 to 5 hours.

- In winter, we advise you to preheat the Resin Part A Only in a hot water bath for around ten minutes. This is not required in summer with a room temp above twenty degrees Celsius.

- Measure out Part A and Part B in separate containers by weight.

- The best calculation to use is 3mm to 5mm per square meter

- Add your Part A to Part B and mix well till blended.

- Use a flat stirrer for mixing. Avoid brutal beating, creating air bubbles.

- Pour out your resin. Use a blue flame torch to pop bubbles.

- Pot Life at 1 liter 10 mins – Cure Time 3 to 5 hours

Tabletop Resin Ultra Fast

$120.00

$150.00

MASSIVE SALE WHILE STOCKS LAST - Normally $44.00 per Litre Resinzwood Finishing Coat Tabletop Resin is evolving with this new high-performance fast, curing epoxy resin developed with a High UV additive added to bring you a product that will protect… read more

Download PDF Here Resinzwood Ultra-Fast Tabletop Resin with Safety Guide and Notes.

Sanding Re -Coating

If you are going to sand and re-coat, you can do this after the first 24 hours. Use an orbital sander with 180 grit sanding discs on low motion, not in gear mode, like the ones on your Festool sanders. If you have done your final pour, there is no need for any sanding, as your tabletop will be perfect without any polishing.

Blemishes imperfections

Many factors can cause blemishes or the look of snail trails on Any epoxy resins, and in most cases with any brand of epoxy, this is caused by too much humidity. Back in the early days, with inferior resins compared to our Resinzwood Ultra-Fast, this was just part and parcel, and you will find this to be exaggerated with other brands on the market today due to the grade of the epoxy they sell. Generally, snail trail effects or blemishes are easily fixed using a cutting compound followed by a polishing compound. But 99 percent of the time, you will not encounter this with Resinzwood Ultra-Fast resin.

cases with any brand of epoxy, this is caused by too much humidity. Back in the early days, with inferior resins compared to our Resinzwood Ultra-Fast, this was just part and parcel, and you will find this to be exaggerated with other brands on the market today due to the grade of the epoxy they sell. Generally, snail trail effects or blemishes are easily fixed using a cutting compound followed by a polishing compound. But 99 percent of the time, you will not encounter this with Resinzwood Ultra-Fast resin.

In severe cases of snail trails, you have two options. We recommend that you sand and re-coat your top, keeping the room hotter and humidity low by using a dehumidifier. If you feel that you want to go through the sanding option, as some folks have told me, they like to do this old-school style, use the guide below.

How To Sand and Polish

This option is not really ever required for any of our resins, but I have included it here as a guide in case you want to use or try it.

Sand your top. You will start at 240 grit and go up from there.

- Use 240, 320, 400 grits dry sanding

- Then use 600, 800, 1000, 1200, 1500, 2000, 3000, and 5000 grits wet with water and a little dishwashing liquid to aid the sanding process. This is ready for polishing if you have sanded each layer correctly, removing the sanding marks from the previous grit.

Need More Help?

If you need more help, Paul is available by phone seven days a week from 8 a.m. until 11 p.m. Call him on 021966387. We are committed to helping all our clients get the best results. If this resin is not the best option for your project, we will guide you through the process of choosing the right one.

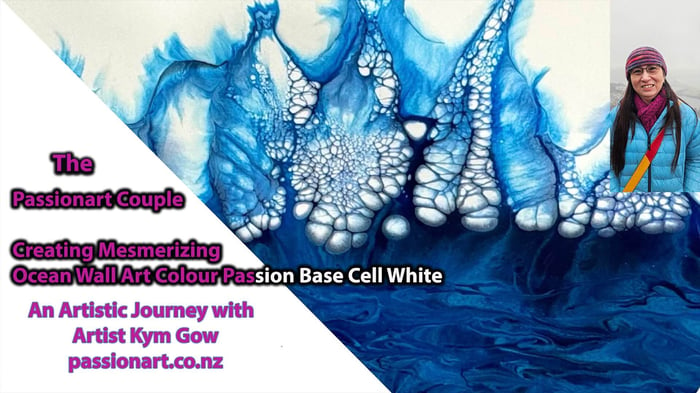

Video Testimonials for Resinzwood Ultra-Fast Resin

Watch these videos below of people from DIY Home table makers and artists, and seasoned professionals who use and love our resins.

Resinzwood Ultra-Fast Resin MSDS Resinzwood Part A MSDS - Resinzwood MSDS Part B